As a technology leader in our industry, we value a reliable supply chain. Our procurement processes are designed to secure high-quality materials and components at competitive prices. We work closely with our suppliers to develop sustainable and efficient solutions that meet both the standards of our product requirements and the high expectations of our customers. Here you will find relevant information about the Knorr-Bremse purchasing organization.

Our purchasing principles.

We strive for long-term partnerships and focus on key suppliers. Working together with our suppliers, we aim to continuously optimize supply chain management and improve product quality and delivery reliability. It is also important to us to reduce material costs, for example through value analyses, standardization, volume bundling, KANBAN, consignment stocks or material substitution.

What we expect from our suppliers:

Our terms and conditions of purchasing and ordering.

The legal relations between our suppliers and Knorr-Bremse are governed by the General Terms and Conditions of Purchasing and Ordering of the respective country and any other written agreements. For more information, please visit our different purchasing areas:

Terms and Conditions Direct Purchasing Rail Vehicle Systems

Terms and Conditions Direct Purchasing Commercial Vehicle Systems

Sustainable Purchasing

Our quality guidelines.

As a technology pioneer for braking systems in the rail and commercial vehicle sectors, Knorr-Bremse is constantly working to expand its own areas of expertise and, as a global systems supplier, to be a strong partner in developing modern braking and on-board systems. This can only be achieved through close cooperation with our suppliers.

Knorr-Bremse’s Quality Management Directive for Purchasing forms the basis for a close and long-term successful partnership to continuously improve the overall purchasing process, quality and productivity. Our Quality Management Directives for Purchasing, as well as the included standard N20000, can be downloaded our purchasing department's sections:

Direct Purchasing Rail Vehicle Systems

Direct Purchasing Commercial Vehicle Systems

Indirect Purchasing

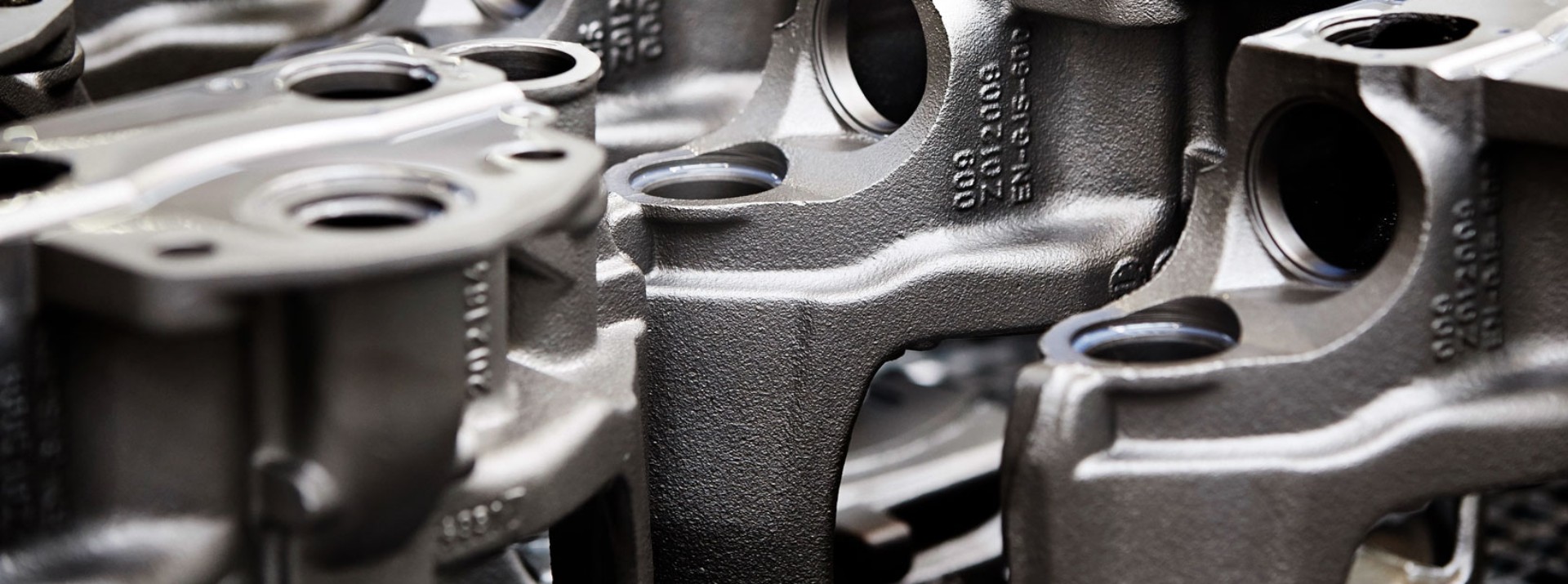

Our requirements. Product groups and purchasing volumes.

Purchasing at Knorr-Bremse is organized according to product groups and managed centrally for all our sites and products. Central product group management forms the basis for demand-oriented procurement. Purchasing volumes vary across different company units. Generally, the purchasing department handles both smaller quantities, such as those needed in the project business for rail vehicle systems, and larger quantities typical in the series production of commercial vehicles.

Below you can find an overview of our product groups:

Purchasing departments of Knorr-Bremse

Direct Purchasing for Rail Vehicle Systems (RVS)

We procure goods and services that are directly incorporated into the products of our Rail Vehicle Systems division. These resources are all integrated into the end products that we deliver to our customers and are essential for the manufacture of our products.

Read more

Direct Purchasing for Commercial Vehicle Systems (CVS)

We procure goods and services that are directly integrated into the manufacture of our products in the Commercial Vehicle Systems division. These are integral components of the products that we supply to our customers. They are absolutely necessary for the manufacture of our products.

Read more

Purchasing for Indirect Material

We focus on the cross-divisional procurement of goods and services that are essential for the day-to-day operations and support functions of our business (e.g. office supplies, IT hardware and software or maintenance services). These are not used directly in the manufacture of our products.

Read more